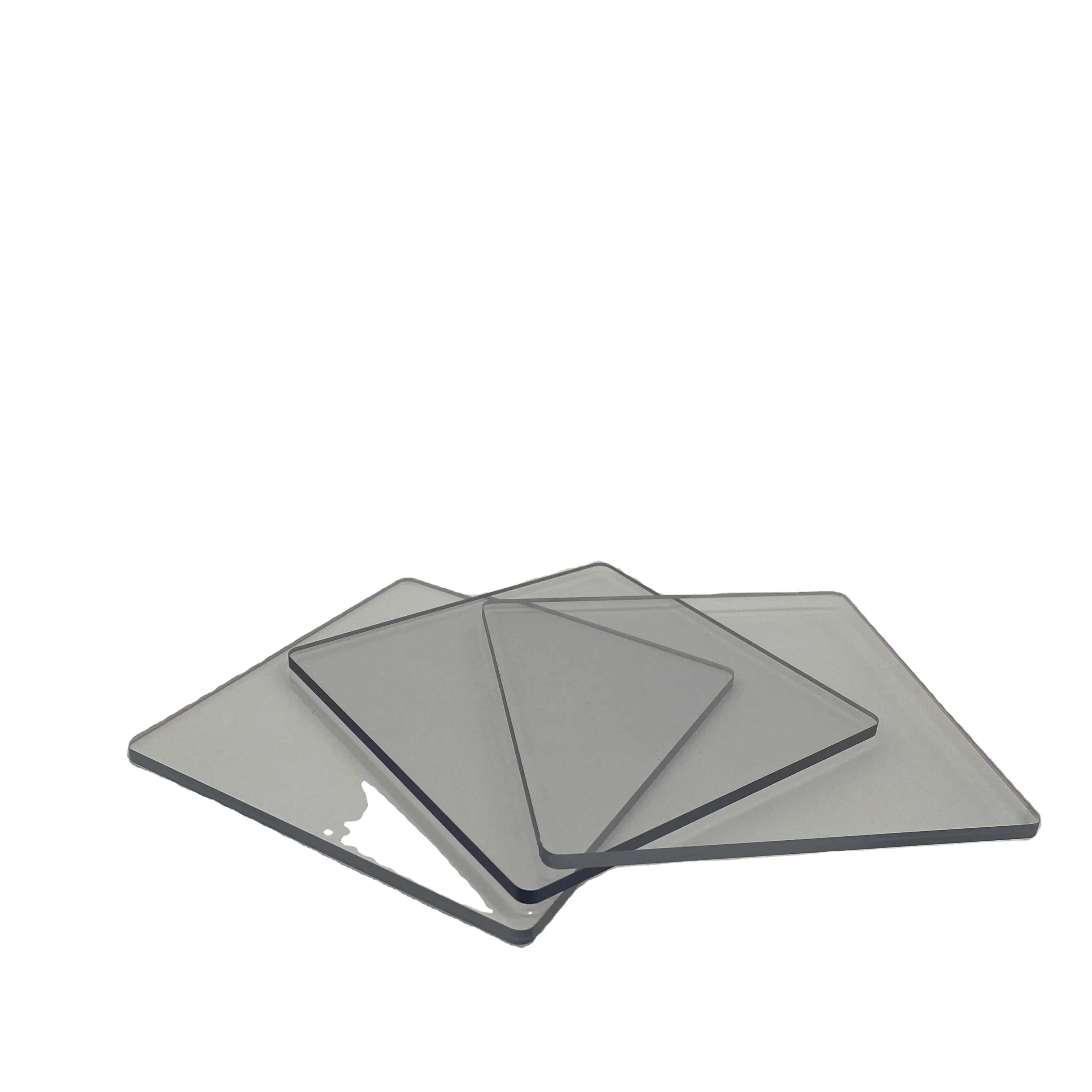

Polycarbonate sheets are transparent or even translucent material, which is used for the greenhouse. Also known as perforated polycarbonate sheets, this type of plastic has small holes. These sheets are very light in weight and strong, which makes them impossible to break even if dropped. These features make them suitable for many services such as roofing, walling and lining walls or to soundproof areas when fitted between rigid frames.

and the many benefits perforated polycarbonate sheets offer. They are also able to allow air, light and sound pass freely. This feature also means that indoor spaces stay cooler and quieter - a win-win on the comfort front. Furthermore, it can also provide some privacy since they do not afford a totally see-through panel and that means the sunlight cannot directly contact your skin as well as other harmful rays. Perforated sheets come in variety of colors, sizes and designs so you can easily get right the one which suits your requirement. They are also extremely simple to clean and put down, making it great as a choice for those who want something easy. On top of this, they are eco-friendly as well - and recyclable and reusable materials helps waste-production.

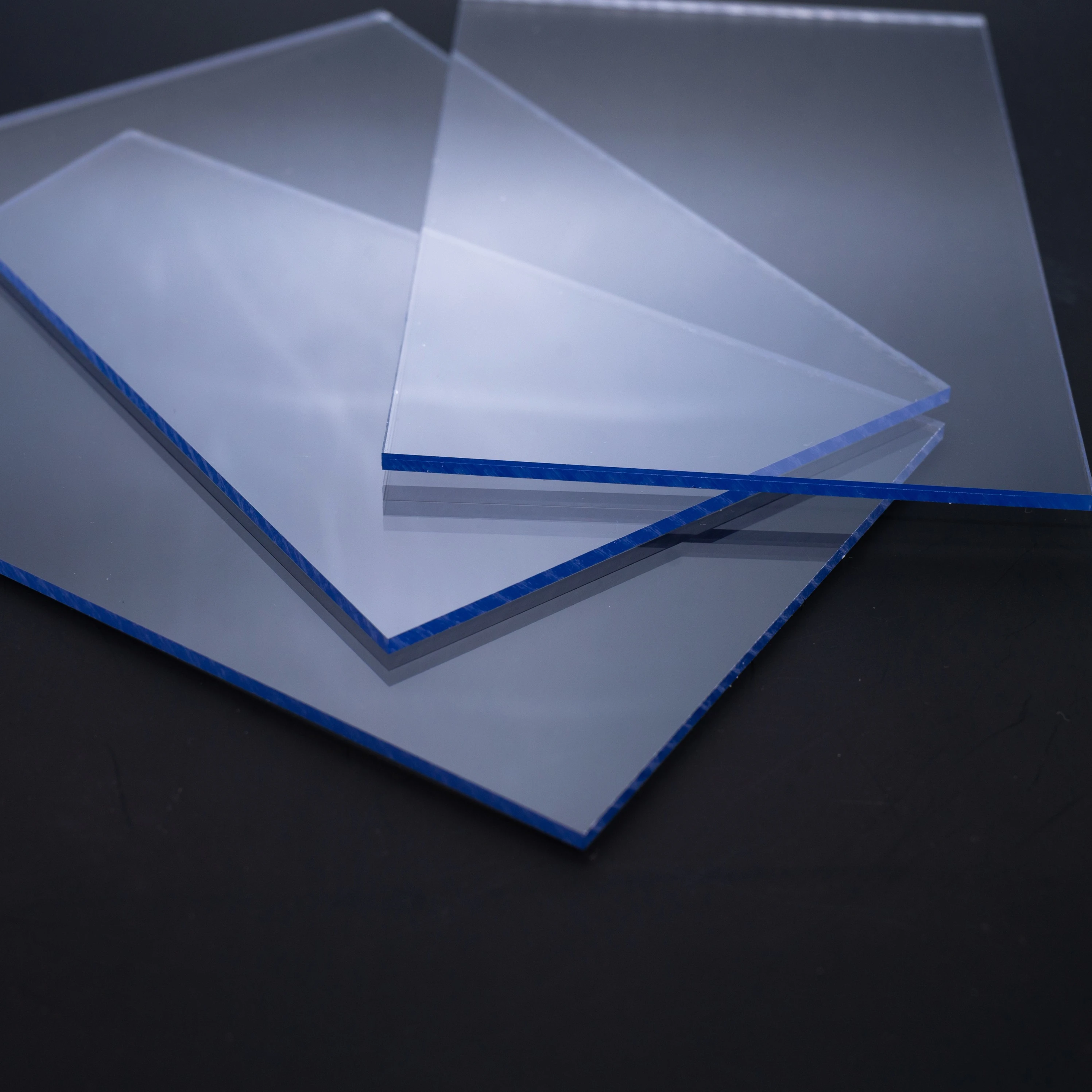

Perforated Polycarbonate Sheets: The Look, Pros and Design Inspiration This can include everything from spreading them across buildings, fences and walls to give a modern look based on the surface. RoofingMaterials These are used for skylights, canopies Roofingsystems to allow natural light in and provide cover from the elements Within office facilities or studios, these sheets could work as dividers to divide the space with a minimal blockage of light and sound. Artistically speaking, they can also be utilized to create creative signs or used for murals as a whole. You are able to craft creative and attractive designs that will be unique, once paired with other materials such as metal, wood or even glass.

Perforated Polycarbonate Sheets Are an Affordable Option One of the greatest attractions to using perforated polycarbonate sheets is that they save you money in a variety of ways. For one, they are typically cheaper than glass or metal sheets, offering an economical solution. They are also made to be long-lasting, which means that you will not have a higher cost for repairs or replacements. Not only thin enough to be relatively lightweight and easily transportable for their installation process, this is also a great way to save time on labor. You can further mold them to fit the shape that you want, which is good for not wasting a lot of material. They also can be energy efficient, thus upping the ante on your electricity savings. Last but not least, this resistance to impacts, fire and weather could reduce insurance expenses on the properties in question, increasing their appeal even more.

Perforated polycarbonate sheets are created using a manufacturing process known as extrusion. Polycarbonate Plastic, small pellets are then heated until they melt So you can see we have this flat sheet and when it is hot, the plastic comes as a flat-sheet. Well, the machines in which holes are made one after alloy steel sheets manufacturer makewith another and at regular interval distance. These holes can be made to size, shape and spacing according to the application of sheets. Afterwards the sheets are placed on rollers and air dried, sent to be cut depending on size standardisation then packaged for delivery. Such a mode of production can be done by the machine itself, hence utilizes less manpower and time in addition to low labor costs making quite an effective manufacturing process for these sheets.

The installation of perforated polycarbonate sheets in your project is a simple process. Accommodating what you need the sheets for in terms of size and hole pattern establishment. Seeing a manufacturer or designer to help with the technical side of your project is wise. Next you pick the color and texture of sheets to match perfectly into your overall decoration. You can even add lighting or graphics that work well with the sheets, to give them a more inviting and professional look. Installation: Screw, Glue and Clip. To clean the sheets, use only soap and water or a light detergent to ensure that they last as long as possible.